Why Composites are Transforming Building And Construction Materials

Why Composites are Transforming Building And Construction Materials

Blog Article

Checking Out the Uses and Advantages of Recycled Composites in Modern Industries

The amalgamation of recycled materials with sophisticated composite technologies provides an encouraging avenue for enhancing sustainability, durability, and cost-efficiency throughout numerous markets. As industries seek ingenious options to resolve ecological concerns and boost functional effectiveness, the unification of recycled composites emerges as an engaging option.

Environmental Benefits of Recycled Compounds

The utilization of recycled composites in contemporary markets provides substantial environmental advantages, adding to the decrease of waste and the preservation of natural resources. By integrating recycled composites into manufacturing processes, industries can decrease their reliance on virgin products, therefore reducing the quantity of waste produced and the power needed for removal and production. This shift in the direction of using recycled compounds aids in drawing away materials from landfills, relieving the worry on waste monitoring systems, and reducing greenhouse gas discharges associated with traditional production techniques.

In addition, making use of recycled composites promotes the preservation of natural deposits such as wood, minerals, and water, which are typically depleted via the extraction and processing of basic materials (composites). By expanding the life expectancy of materials with recycling, markets can assist preserve ecosystems and biodiversity by lowering the demand for brand-new sources. Generally, the adoption of recycled compounds in contemporary sectors plays a critical function in promoting sustainability and mitigating the environmental effect of manufacturing processes

Enhanced Durability in Item Production

With an emphasis on longevity and robustness, integrating recycled composites right into product production procedures boosts toughness and sustainability. By using recycled compounds, makers can create products that are not just strong however also resistant to tear and wear, making them excellent for long-lasting use in different sectors. The combination of various products in recycled composites can frequently lead to enhanced strength and longevity contrasted to traditional products, giving an economical solution for creating resilient goods.

One of the vital benefits of utilizing recycled compounds in item production is the capacity to tailor the product homes to satisfy details resilience demands. By changing the make-up and production techniques, makers can personalize the recycled compounds to hold up against rough ecological conditions, heavy tons, or regular use without jeopardizing on efficiency. This versatility in layout and manufacturing enables the creation of highly durable products that preserve their stability in time, minimizing the requirement for regular substitutes and inevitably adding to a much more sustainable manufacturing procedure.

Cost-Effectiveness and Economic Benefits

Integrating recycled composites into product manufacturing not only boosts longevity and sustainability yet likewise offers substantial cost-effectiveness and economic advantages. Making use of recycled compounds can result in lowered product expenses as recycled products are often less costly than virgin materials. Furthermore, recycling composite materials can lower garbage disposal expenditures and decrease the need for landfill room, adding to overall expense financial savings for sectors.

Advancement and Style Adaptability With Recycled Compounds

Using recycled composites in modern markets provides exceptional chances for innovation and layout flexibility. By incorporating recycled products into composite manufacturing procedures, business can push the boundaries of typical style restrictions and discover new opportunities. The convenience of recycled composites enables the development of complicated forms and frameworks that could not be achievable with traditional materials.

Among the crucial benefits of recycled compounds is their capability to be formed into numerous forms, providing developers the flexibility to trying out special shapes and dimensions. composites. This flexibility opens up a globe of innovative chances, allowing the growth of lightweight yet resilient products that meet the specific needs of different markets

Additionally, making use of recycled composites advertises sustainable techniques and sustains the circular economic climate by reducing waste and decreasing the ecological influence of manufacturing processes. This emphasis on environmentally friendly layout options straightens with great post to read the growing pattern in the direction of sustainability in contemporary industries, making recycled composites a valuable resource for cutting-edge and forward-thinking companies.

Applications Across Different Industries

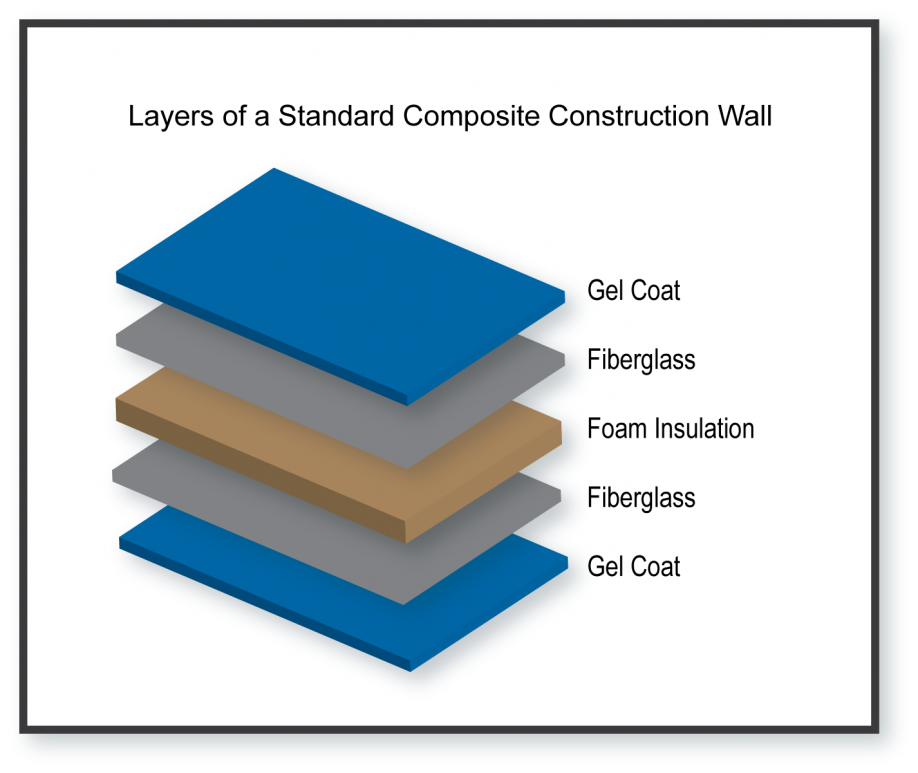

Recycled composites locate impactful and varied applications throughout a wide variety of sectors because of their one-of-a-kind residential properties and sustainability advantages. In the automotive field, these materials are progressively made use of for making sturdy and lightweight parts, improving gas performance and minimizing carbon exhausts. The aerospace industry take advantage of recycled compounds in the production of aircraft components, where the materials' strength-to-weight proportion is crucial for making certain security and efficiency. In building and construction, these composites are used for creating strong yet environment-friendly building products, adding to sustainable infrastructure growth. The renewable power field uses recycled composites in wind turbine blades and solar panels, utilizing their toughness and resistance to harsh environmental problems. In addition, the aquatic market uses these materials for producing watercraft hulls and elements, supplying enhanced durability and rust resistance. The convenience and sustainability of recycled composites make them useful throughout numerous sectors, driving development and environmental stewardship. composites.

Verdict

To conclude, the usage of recycled compounds in modern markets offers significant ecological advantages, enhanced durability in product production, cost-effectiveness, and financial advantages. Moreover, using recycled composites permits innovation and layout adaptability throughout numerous markets. Overall, the adoption of recycled compounds presents a practical and lasting option for fulfilling the demands of the industry while likewise decreasing environmental influence.

One of the key benefits of try this utilizing recycled composites in product manufacturing is the ability to customize the material residential properties to satisfy specific toughness demands. Utilizing recycled compounds can go to my blog lead to minimized material prices as recycled materials are often much less costly than virgin materials. The aerospace market benefits from recycled compounds in the production of aircraft components, where the materials' strength-to-weight proportion is essential for ensuring safety and security and efficiency.

Report this page